How is the XTREME mat Manufactured?

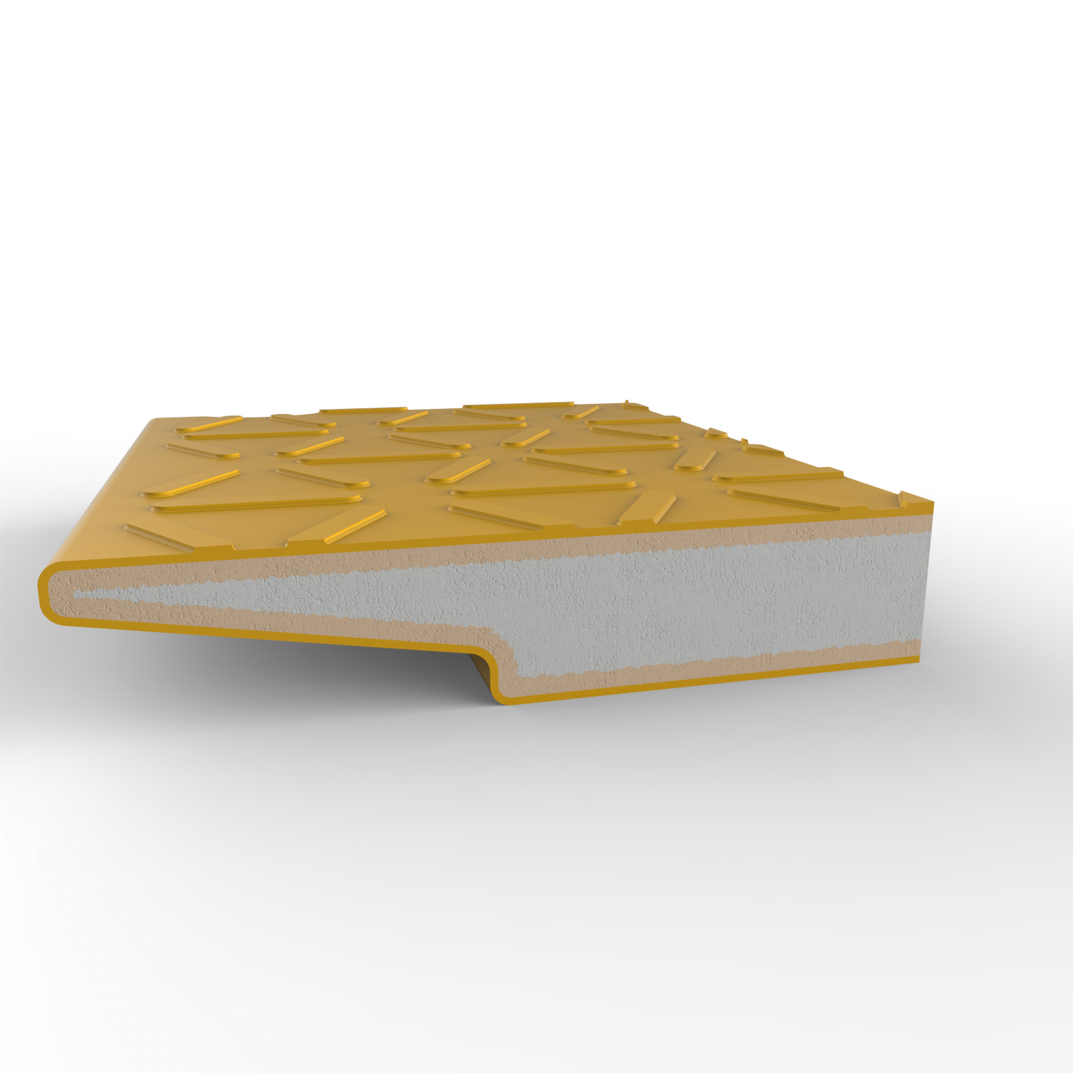

The XTREME Mat is manufactured using a rotational molding (rotomolding) process. Our proprietary rotomolding technique utilizes some of the largest molding machines in the industry, allowing for precise control of material distribution and wall thickness. This advanced process enables the production of large, heavy-duty HDPE mats with a one-piece, solid plastic internal core, resulting in exceptional structural integrity and industry-leading strength.

What is the difference from the XTREME mat to the competitors?

The solid-core construction of the XTREME Mat is unique within the industry. Each mat is manufactured as a single, continuous HDPE structure with an integral solid internal core, unlike competitive designs that rely on seamed, two-piece construction with hollow or honeycomb-style cores.

This one-piece solid-core design delivers significantly greater structural strength and load-bearing capacity. In addition, because there are no internal voids, the core cannot absorb fluids or trap debris—even if the surface is compromised—eliminating the risk of internal contamination or cross-site transfer.

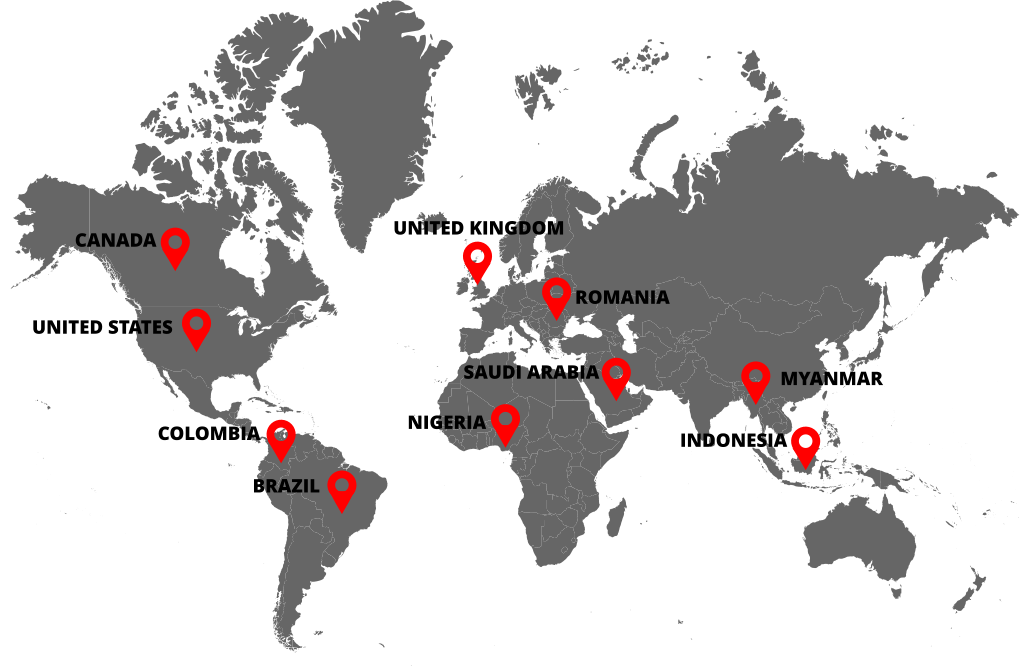

Where is the XTREME mat manufactured and shipped from?

XTREME Mats are manufactured and shipped from Northeastern Canada, in the city of Tracadie-Sheila, New Brunswick. For overseas shipments, the nearest port of departure is Saint John, New Brunswick, providing efficient access to international shipping routes.

What is the compressional load or the XTREME mat?

The XTREME Mat is rated to withstand a compressive load of 828 PSI (56 kg/cm² | 852 ton/m²). In controlled testing, the mat has been subjected to loads approaching nearly twice this rated capacity without structural failure, exhibiting only minimal surface deformation.

This exceptional compressive strength is achieved through the mat’s solid-core design. The internal structure consists of a fully filled, closed-cell HDPE core with no void spaces, creating a homogeneous, one-piece structure. The absence of internal cavities significantly enhances load distribution, structural integrity, and overall strength.

Do you have an Sales Representative in our area?

We primarily sell directly to end users. Our sales team can be contacted through the Contact Us form located at the bottom of this website for product inquiries, pricing, and project support.

What is the maximum weight the XTREME mat can handle under extreme temperature conditions?

XTREME Mats are rated to operate within temperature ranges from −50°C (−58°F) to 60°C (140°F) while maintaining a compressive bearing capacity of 56 kg/cm² (828 PSI | 582 ton/m²)—the highest rating in the industry among comparable matting systems.

Can the XTREME mat be used on a Drilling Rig site??

Yes, many clients successfully utilize XTREME Mats within their rental fleets across a wide range of applications. Common uses include temporary working platforms, access roads, and base layers on drilling rig sites.

As with other comparable composite matting systems, when used as a base layer beneath a drilling rig, rigid rig mats are still required to meet engineering and load-distribution requirements. In these applications, rigid rig mats are typically installed on top of the XTREME Mats to provide additional stability.

Due to the solid HDPE core design and advanced manufacturing technology, the load-bearing capacity of XTREME Mats generally exceeds the engineered minimum requirements for base-layer support, making them a reliable and effective foundation in demanding applications.

Does the XTREME mat fit into standard shipping container?

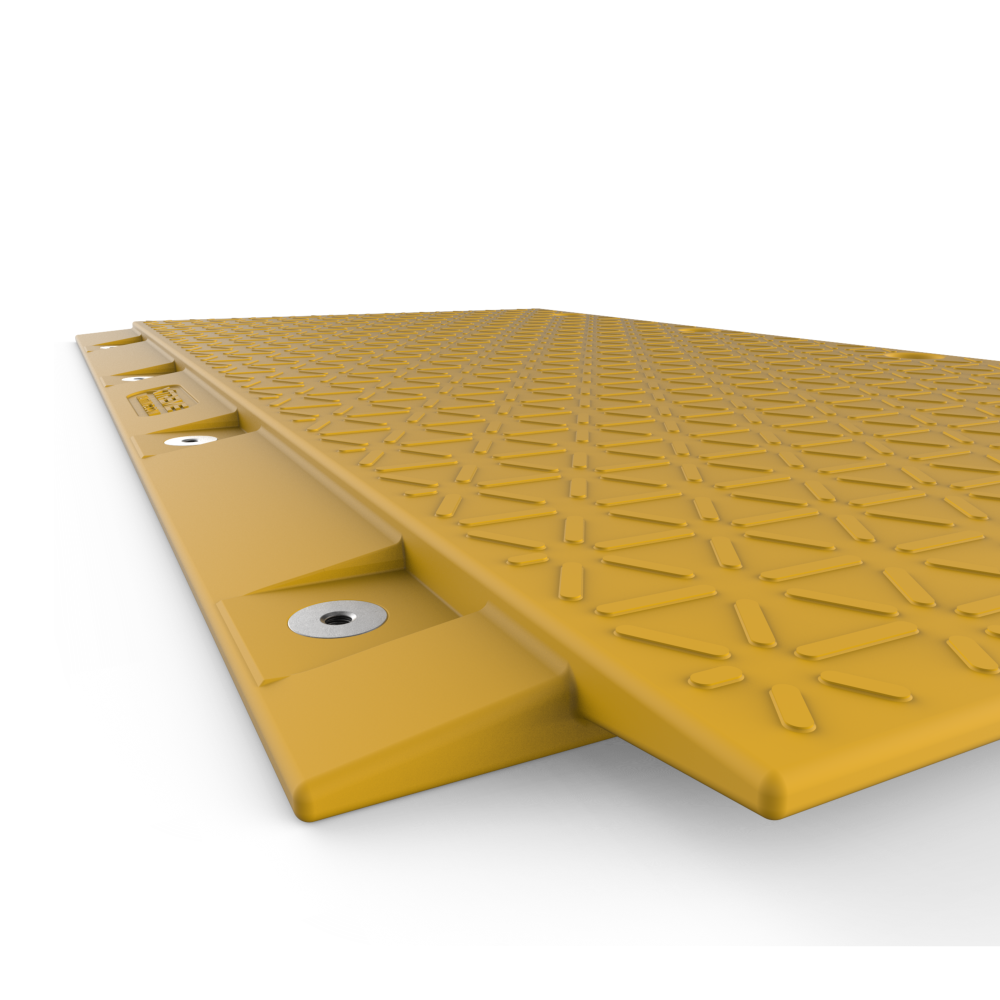

Yes, XTREME Mats are sized to fit safely inside standard shipping containers. Each mat has overall dimensions of 4.34 m (14.25 ft) in length, 2.29 m (7.5 ft) in width, and 100 mm (4 in) in thickness.

A standard 40-foot container typically accommodates up to 40 mats, while a 20-foot container can carry approximately 20 mats, allowing for efficient and cost-effective global shipping

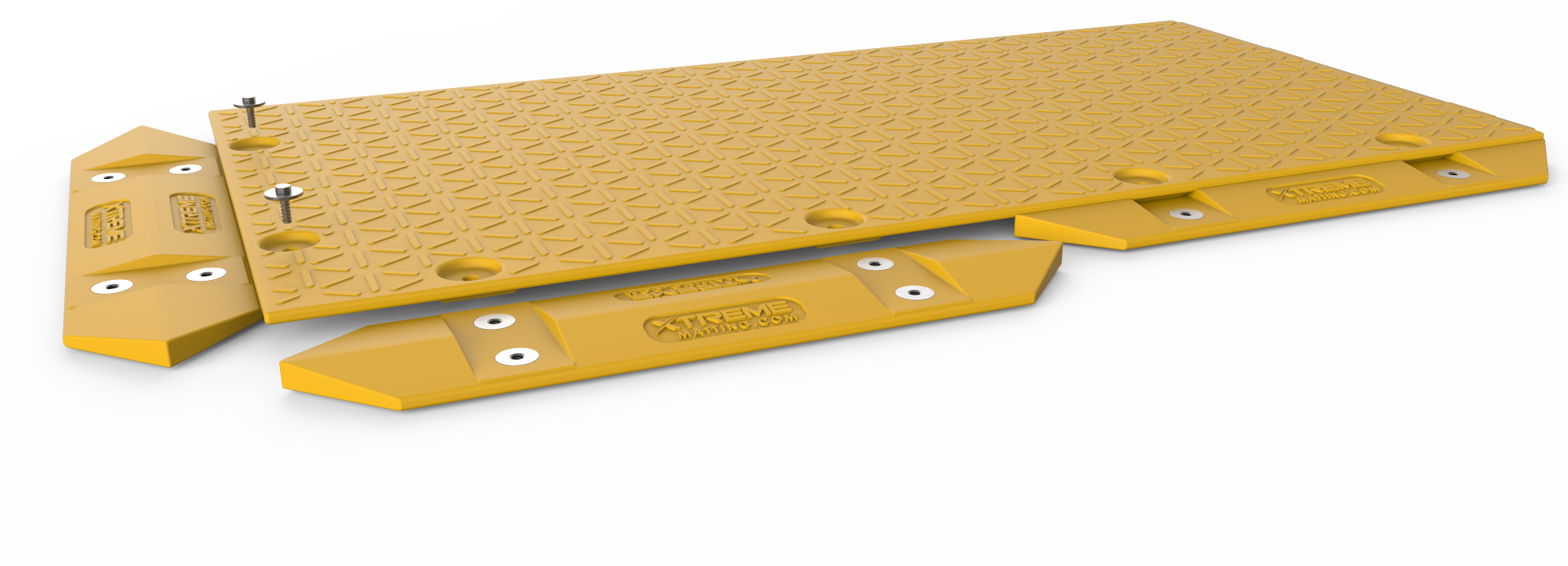

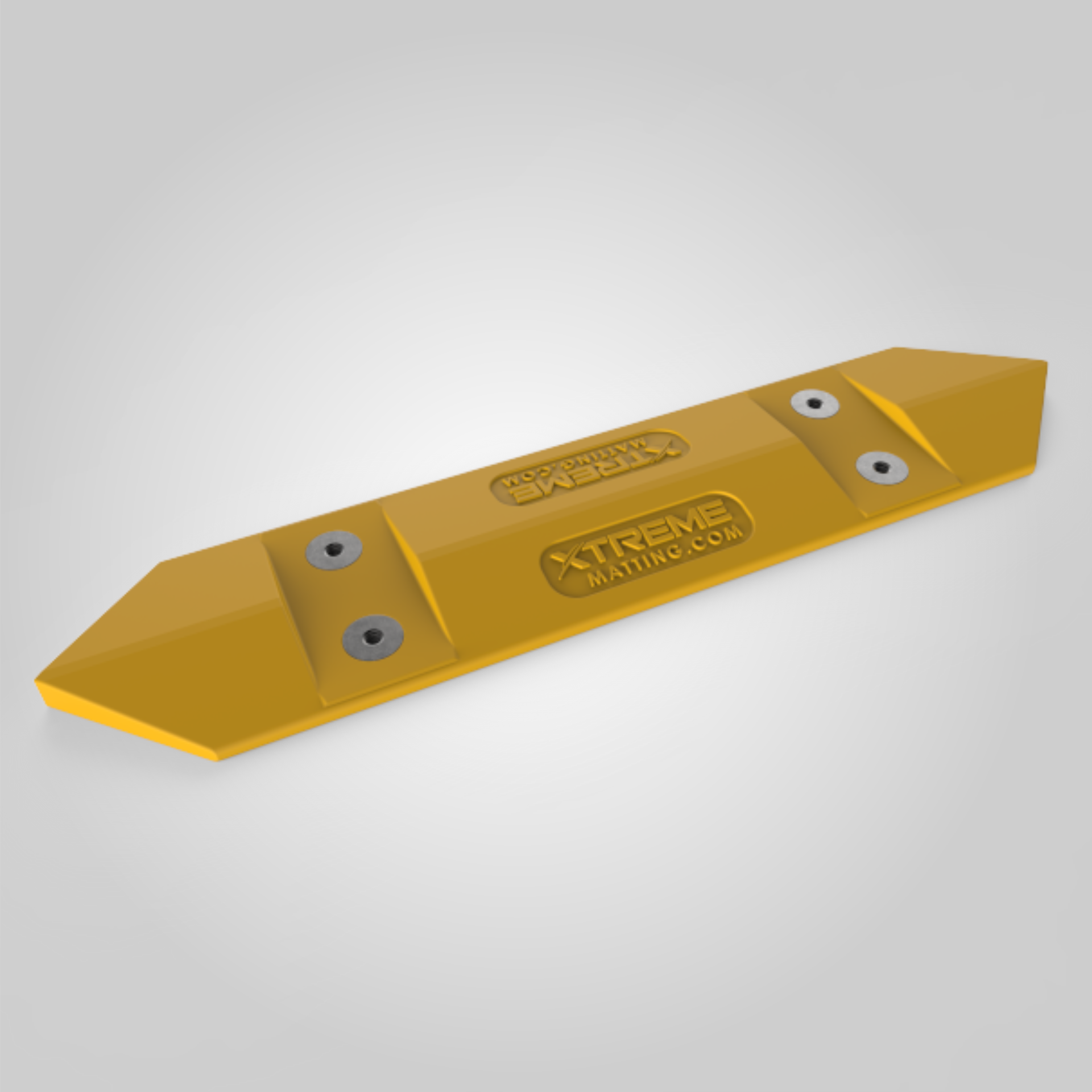

Can the XTREME mat overlap transition connection provide lateral stability for weights over 20 Tons?

Yes, all components of the mat system—including the overlap connections and optional transition support pieces—are engineered to support the same load-bearing capacity of 56 kg/cm² (828 PSI | 582 ton/m²), ensuring consistent strength and performance across the entire system.

Can the XTREME mat be repaired if damaged?

Yes, we offer an optional HDPE welding tool supplied complete with matching HDPE spool material for seam welding or patch repairs. The tool requires minimal training and is designed for efficient, in-field repairs, allowing damaged mats to be quickly restored to service.

Does the XTREME mat use any recycled material and can it be recycled?

The XTREME Mat is manufactured using 100% virgin HDPE material and is up to 99% recyclable at the end of its service life. Depending on regional recycling center rates, the recovered material value typically ranges between $300–$500 USD per mat, supporting both sustainability goals and potential cost recovery.